Continuous Insulation: What is it?

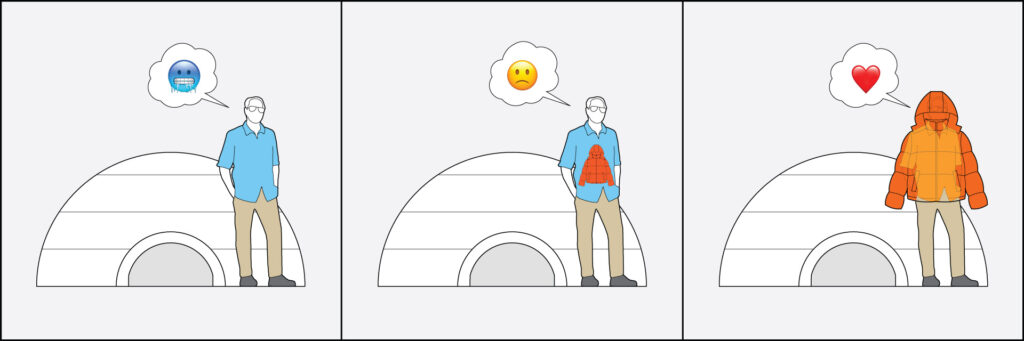

When we are cold, we put on a sweater, right?

We don’t eat the sweater.

That would be not only odd but fundamentally ineffective.

Then, why have we been putting insulation inside the walls of our buildings?

The short, short answer is: it was cheap and convenient to do this way, not that it was fundamentally more effective.

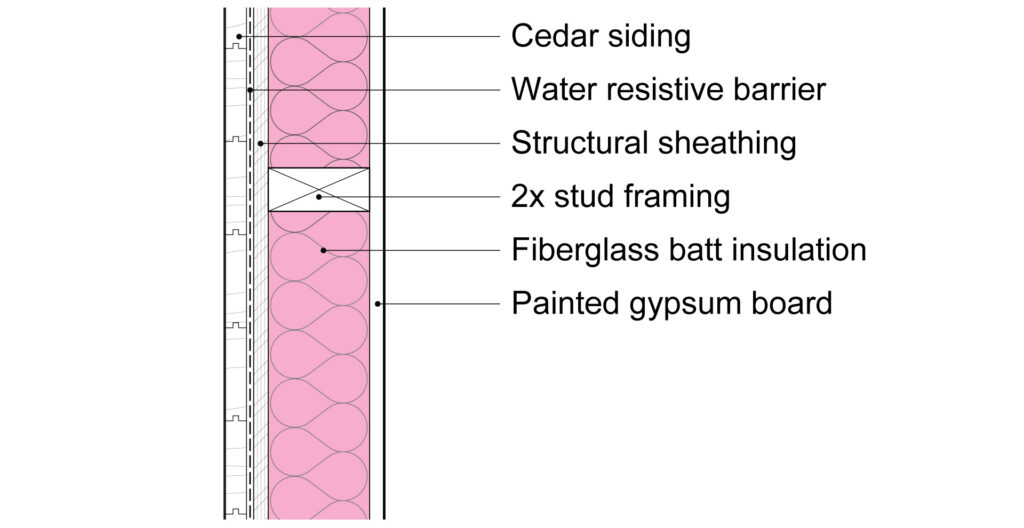

Traditional residential exterior wall construction for many years consisted of 2x4 wood stud framing with fiberglass insulation in the framing cavity. It remains a code-compliant strategy for new construction today when using 2x6 framing. This creates space for the current required R-value even though 2x4s are perfectly serviceable structurally. [See also Up To Code.]

This type of wall system was 1) economical, 2) simple to install, and 3) generally successful, especially in places where seasonal changes were less extreme.

However, it started to reveal its shortcomings as new building systems, materials, and finishes were overlayed on the basic system over the years. Penetrations were made in this shell to hide or route plumbing and electrical elements. Or new wall coverings would change how the wall worked (vinyl wall paper was a big culprit). In areas of high humidity, the wood structure could be susceptible to rot or mold if it didn’t get a chance to dry out. In cold climates, ice damming could ruin ceilings with water damage. With the introduction of air conditioning, the interior air humidity could instigate hidden mold growth.

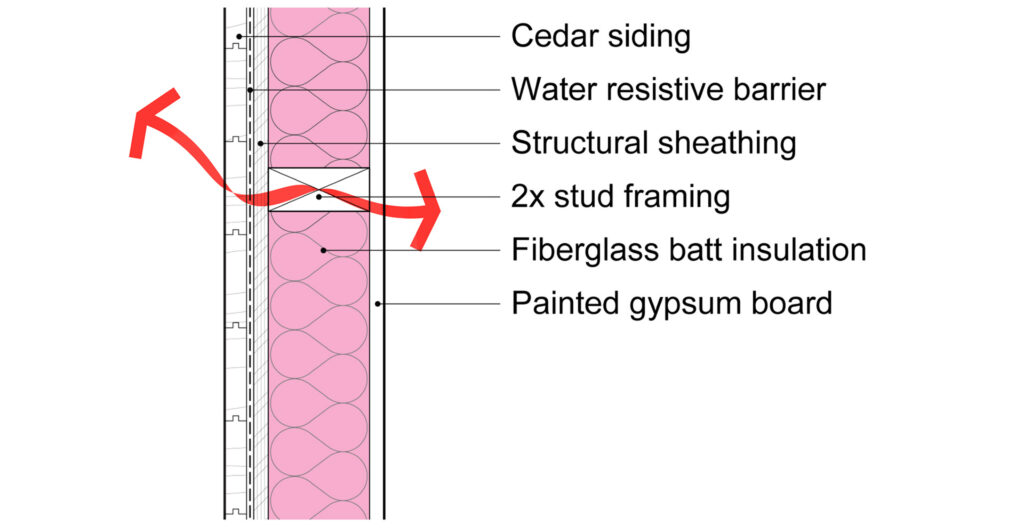

You can see in the wall section diagram above that the stud framing touches both the inside and outside of the wall system without intervening insulation. This creates a thermal bridge—a pathway for energy to transfer across the wall. In cold climates, this leaks heat out of the interior in cold weather. In warm climates, it leaks heat into the inside during hot weather.

So, what to do? Put on a sweater!

In the field of building systems, putting on a sweater is called Continuous Insulation.

So, what exactly is Continuous Insulation?

Continuous insulation, or CI, as defined by ASHRAE Standard 90.1:

Insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior, exterior, or is integral to any opaque surface of the building envelope.

Uh-huh, yeah…what does that mean?

Our sweater is a continuous layer that covers us. In a building, we install a continuous layer of insulation from the ground to the roof. It connects the insulation on the roof, and it connects to the insulation underneath the floor. This encapsulates the interior space and the structure of the house, and it isolates the heating and cooling system from the influence of exterior temperatures. It allows the structure to last longer and perform better without degradation from seasonal or daily temperature swings or differential movement.

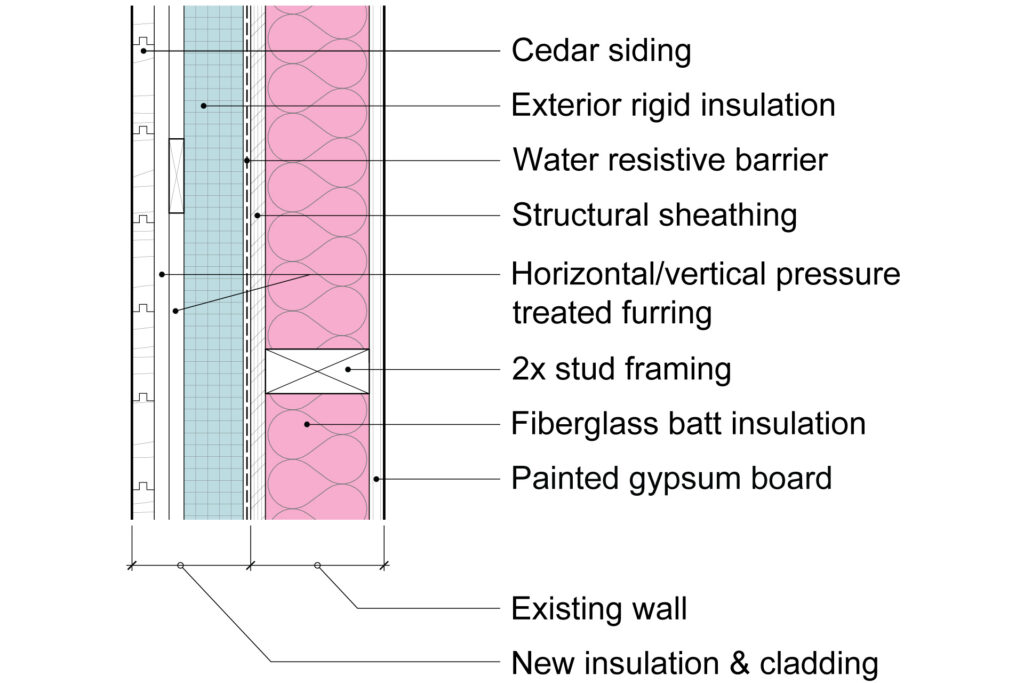

In the diagram below where we improved an existing conventionally insulated wall, the blue layer of exterior rigid insulation creates this protective continuous insulation layer, our metaphoric sweater. It breaks that thermal bridge connecting the siding to the building structure. With the right thickness of continuous insulation, we could even get rid of the fiberglass insulation (pink) in the framing bays. Some designers have used this strategy to eliminate interior drywall and expose the framing bays to the interior for a kind of casual industrial look.

Why is continuous insulation important?

Money spent on the building shell can potentially produce savings for well more than 50 years. Other building systems, like mechanical or electrical equipment (including solar systems), only have a ten to twenty-year lifespan before requiring replacement or upgrade. Further, they require regular maintenance and parts that have annual replacement schedules (filters, lamps, etc).

Insulating the building shell beyond code is probably the highest added value system for the life of the building. As part of the building shell, it protects the structure and interior environment from damage and degradation. If maximized at the time of construction, it will likely never get replaced during the lifespan of the building.

What does it look like?

Once the building is finished, this insulating layer is invisible to the world. But it’s good to see what might be under the siding. It can take on a variety of arrangements and thicknesses, but the concept is always the same.

In our Studio, we captured the exterior rigid insulation (light blue) with 1×3 pressure treated plywood furring strips. These were nailed through to the structural studs. The furring strips do not touch each other which provides a continuous pathway around their ends for air to circulate behind the siding. The top and bottom of the wall have a breathable black insect barrier to keep critters out of the wall gap.

Some of the implications of selecting a continuous insulation wall design include:

- Thicker walls than traditional construction.

- Thicker door and window trims.

- Special attention is needed for common building penetrations like piping, conduit, or air exhausts/intakes.

- Special attention for continuity of insulation at the floor and roof.

- Higher performing envelope allows lower energy consumption for hvac and often smaller design sizing of equipment.

- This is a long term upgrade that doesn’t require yearly maintenance.

These are all easy items for your architect to coordinate as part of a holistic design strategy. This strategy can even be used as a retrofit to an existing structure, as we did for the Hayden Island Facelift.

Continuous insulation (outsulation, exterior insulation, or whatever you want to call it) works better in all climates.

Whether in balmy southern California, the desert, the mountains, or here in the Pacific Northwet, using continuous insulation adds value to the life of your home or office.

Want to learn more about continuous insulation? Or are you ready to build or upgrade a building? Give us a call.